Fluid Distribution

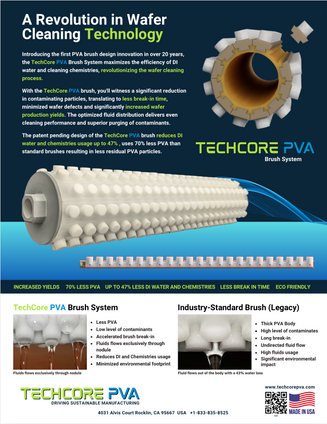

Industry-Standard PVA Brush (Legacy)

Industry-Standard PVA brushes suffer from unregulated fluid flow, causing the entire PVA body to become saturated.

As a result, water exits primarily through the outer wall of the brush, rendering the central body ineffective for wafer cleaning.

This loss of fluid through the PVA body leads to insufficient fluids flow on the nodules' surface, reducing its ability to flush out trapped contaminants.

Industry-standard brush showing fluid loss through body

TechCore PVA brush showing fluid directed through nodules

TechCore PVA Brush System

The TechCore PVA brush is specifically engineered to optimize fluid flow, volume, and direction for effective wafer cleaning and contaminant removal.

By enclosing the PVA within plastic rails and limiting fluid contact to the cleaning nodules, fluid can only exit directly through these nodules, enhancing on the cleaning process while purging particles.

Internal channels within the nodules create a direct and unobstructed pathway for fluid to reach the tip of the nodule, where it interfaces with the wafer.

This unique design surpasses any other brush currently available in the market.

DI Water and Cleaning Chemistries Distribution Pattern

This distribution test shows the relative amount of fluids coming from each section of the brushes. The TechCore PVA brush has optimized fluid delivery across the length of the brush, resulting in virtually even distribution leading to better cleaning of the wafer, better purging of nodule contaminates while drastically reducing expensive fluid usage.

Industry-Standard PVA Brush

Observe the uneven waterflow pattern across the standard PVA brush, as depicted in the DI Water and Cleaning Chemistries Distribution Test. These irregularities in fluid distribution can lead to areas with insufficient water, posing a risk of damage to the wafer and subsequently reducing yields.

Industry-Standard Brush

TechCore PVA Brush

TechCore PVA Brush System

The TechCore PVA brush achieves remarkably even water distribution along the entire length of the brush. This optimized fluid flow ensures consistent and effective cleaning of the wafer, superior purging of nodule contaminates, and, notably, a substantial reduction in costly fluid usage.

Liquid Particle Count (Particle Measuring Systems CLS 700 T)

Ion Chromatography (Dionex ICS-5000+)

Material Properties

* Compressive value can be customized

Third Party Tested Trace Metal Contaminations (ICP-AES)